Here in this article, the actual centrifugal pump we referring to is a device designed along with engineered to handle abrasive, viscous and corrosive fluids inside drilling fluid or professional slurry applications. With the functionality matched by exceptional overall performance, high volume, high temperature features, long service life, easy for upkeep, overall economy and higher savings. Currently, this type pump motor is widely used in operation in land-based and offshore going rigs around the world.

In regards to the going industry, the centrifugal pump could be used to transfer the particular drilling fluids, mixing the harmful chemicals into the fluids. Thus this always be equipped in the providing pump system for giving drilling mud to de-sander and de-silter and fly mud mixer unit for a mixing pump. Besides, it is also used as trip water pump used to feed the going fluids into deep straight down well when changing the going pipe and supercharging send for rig high pressure magnetic pump.

GN Centrifugal pump Advantages are as listed below:

1 . The much plumper housing is for extra power and extended service life. Often the concentric design housing removes turbulence and cavitations inside pump, and it also reduces the actual radial load on the bearings.

2 . The open vane impeller is designed to reduce désordre, lower radial and press loads, and provides a simple flow of fluid with the pump.

3. The tube shaft with a large height ensures the heavy duty effectiveness with minimal shaft defection. The shaft sleeve in addition to mechanical seal can be substituted without removing the canal from the pump.

4. GN centrifugal pump adopts kinetic type seal which is manufactured from the best material so far worldwide. This type seal delivers excellent performance with superior style. Our seal distributes push torque over 10 commute tabs, which greatly minimizes stress on the outer retainer-like.

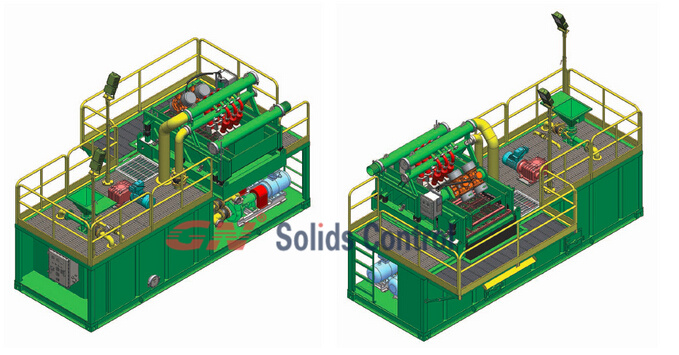

GN Solids Control offers the centrifugal pump together with capacity from 198 for you to 1400 GPM. All the pump motor is provided with explosion proof generator and the pump package could possibly perform well during the area together with ambient temperature of subzero 40 to above cold 60 degree Celsius.