Jet mud mixing system is a normal and necessary part of most kind of drilling mud systems and liquid mud plant (LMP). It is used to prepare new mud and qualified mud, and service for drilling activities. The mud mixing system can be used to mix oil based mud (OBM), water based mud (WBM), as well as synthetic based mud (SBM).

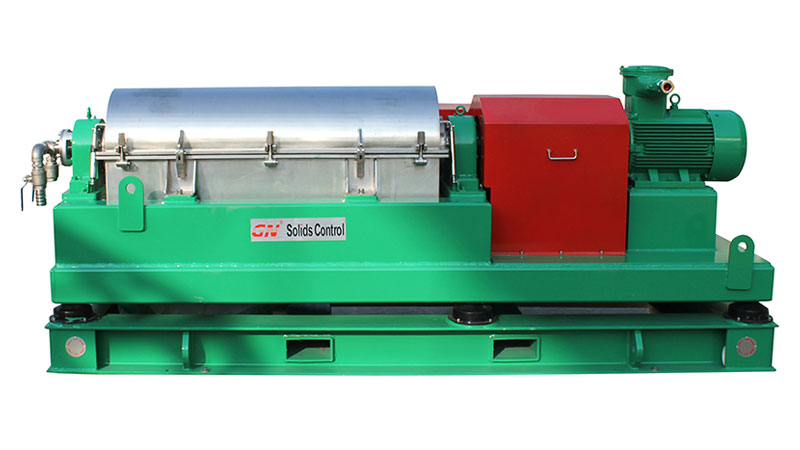

Jet mud mixing system is actually a combination of mixing pump, mixing hopper and control panel. All of them connected by pipelines, they can be mounted on the tank separately per tank layout. They can also be mounted on the same skid as a complete unit.

The jet mixing hopper is also called shearing hopper. It can be mounted on different position of the mud cleaning system for different purpose.

Centrifugal pump is the most popular pump model for jet mud mixing system. Another pump model is shearing hopper. Clients can choose motor drive mixing pump, or diesel engine drive mixing pump, to meet for different demands.

Different position of jet mixing hopper for mixing system

1) The jet mixing hopper can be mounted on the top of the mud tank. Advantage of the tank top hopper is easy for mixing chemical as the gravity. But you should to consider lifting of the chemicals. Sometimes, it is even 1 ton big bag. you should consider the necessary device to help for the chemical lifting. Operation table and crane cradle is the popular way to service for it.

2) The normal way is to put the shearing mixing hopper on the tank skid, next to centrifugal mixing pump. The mixing performance may not as good as on the tank top, but also acceptable. And it is easier for the chemical lifting.

3) Another way for the shearing hopper is on a separate skid with centrifugal mixing pump and control system. The complete is in a separate skid. It is more flexible for application. Users is easy to more the mixing unit from one jobsite to another jobsite, or move it from one tank for another.