The Working Process of GN Oil Sludge Treating Equipment

GN Solids Control manufactures varieties of sludge treating equipment. Oil sludge or industrial sludge is two typical sludge that clients are treating quite often with the increasing demands and awareness of environment protection.

GN Solids Control provides turnkey solution for oil sludge treatment. So how the working process of oil sludge with GN equipments?

1. An excavator is used to put the oil sludge in one Feeding Hopper with screw conveyor. The large V-type hopper is used to collect the all those sludge before feeding into one Sludge Washing Machine.

2. The GN Sludge Washing Machine is fixed with hot water and steam feeding pipes as well as mud agitators. Hot water and SAS chemicals are added into the oil sludge and hot steam is also feed into the sludge washing tank in order to have a better fluidity.

3. GN Hi-G Shaker (G force up to 8.0G) will separating the oil sludge that feed by one screw pump. GN Screw Pump is using the world famous brand—Netzch. Here the oil sludge is separated into two parts: oil slurry (a little bit cleaner) and coarse solids (oil is less than 2%).

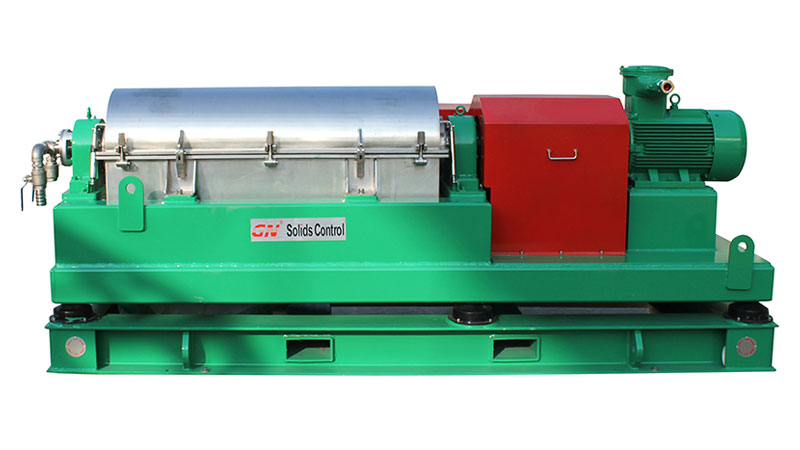

4. With the help of one GN Flocculants System, those oil slurry will be pumped into GN decanter centrifuge. GN centrifuges are widely used for 2 phase separation. Solids larger than 2-5 microns can be separated out by GN decanter centrifuge. By adding some chemicals in the oil slurry, small solids will be gathered and separated out. And the fine solids can be further treated by one TDU to eliminate all the oil in the solids.

5. For those liquids discharged from decanter centrifuge, they will be send into one Oil and Water Separator. Then the clean oil and clean water can be carried and transported to other work sites. Besides, the recycled water can be send to a heater to provide hot steam and hot water.